Towing equipment

Your towing vehicle and trailer need the correct equipment to meet legal and safety requirements.

In this section:

Tow bars

A properly designed and fitted tow bar is essential for safe towing.

Load capacity

The load capacity of a tow bar must be at least equal to the loaded mass of the trailer. All tow bars manufactured after 1 January 1992 for passenger vehicles must be marked showing their load capacity as well as the make and model of the vehicle they are intended to be fitted to.

Attachments

The tow bar must be fitted with attachments for connecting safety chains that can withstand the rated load capacity of the tow bar.

Ensure the safety chain attachments are mounted adjacent to the tow coupling and arranged to maintain the towed vehicle's direction if the coupling fails or disconnects.

Tow bars, including tow bar tongues, must not have sharp edges and corners or overhang dangerously when a trailer isn't connected. The use of a removable trailer ball mount, protective guard on protruding sections, and/or recessed tow bar is recommended.

Removable trailer ball mount

Protective guard

Recessed tow bar

Couplings

Tow coupling

The safe connection of a trailer to a vehicle is only as strong as the weakest link.

Light trailers that do not exceed 3,500kg ATM must have a quick release coupling which is designed to be engaged and disengaged without the use of tools. It must be of a positive locking type with provision for a second independent locking device. The locking must be readily verifiable by visual inspection.

Typical approved couplings for light trailers are:

- Heavy duty 50mm couplings for trailers with an ATM up to 3,500kg

- Pintle hook couplings for trailers with an ATM up to 4,500kg.

Couplings should be marked with their load capacity and the manufacturer's name or trademark.

Safety chains

All pig trailers with rigid drawbars (with or without breakaway brakes but excluding converter dollies) and any other trailer without breakaway brakes, must be fitted with safety chains that are marked in accordance with the relevant Australian Standard complying with the following:

- Trailers that do not exceed 2,500kg ATM must have at least one safety chain complying with Australian Standard AS 4177.4-2004 'Caravan and light trailer towing components Part 4: Safety chains up to 3,500kg capacity' or be a safety cable with a certified load capacity of the same rating.

- Trailers over 2,500kg and not exceeding 3,500kg ATM must have two safety chains of designation of 3,500kg complying with Australian Standards AS 4177.4-1994 or Australian Standards AS 4177.4-2004. Safety cables with the same certified load rating can also be used.

- Trailers over 3,500kg ATM must have two safety chains made from steel of a minimum 800 Mpa breaking stress that conforms to the mechanical properties of Grade T chain as specified in Australian Standards AS 2321-1979 'Short link chain for lifting purposes (uncalibrated)' or Australian Standard AS 2321-2006 'Short link chain for lifting purposes'. Each chain must be sized such that the minimum breaking load exceeds the ATM.

The length of the safety chain/s must prevent the trailer's drawbar hitting the ground if the trailer is detached from the towing vehicle. The safety chains must be properly connected to the tow bar with attachments capable of withstanding the specified breaking load of each chain. Do not use padlocks.

Shackles

Safety chain(s) must be suitably and appropriately connected to a tow bar. The use of a shackle to attach a safety chain to the tow bar is permitted, provided the shackle used is fit for purpose and compatible with the safety chain in terms of strength and size.

You can use a shackle that is compatible with the safety chain and complies with Australian Standard AS 2741-2002 'Shackles'.

Guide to selecting shackles

| Trailer ATM (kg) | Chain size classification (AS 4177.4-2004) | Chain marking (AS 4177.4-2004) | Suitable rated D shackle size (AS 2741-2002) Grade 'S' or '6 dee' or '6 bow' | Minimum proof load strength (kN) chain / shackle |

|---|---|---|---|---|

| Up to 1,000 |

1,000 At least one chain must be used | 4177-10 |

6mm S WLL 0.5T | 4.9 / 9.9 |

| Up to 1,600 |

1,600 At least one chain must be used | 4177-16 |

6mm S WLL 0.5T | 7.9 / 9.9 |

| Up to 2,500 |

2,500 At least one chain must be used | 4177-25 |

8mm S WLL 0.75T | 12.3 / 14.8 |

| Up to 3,500 |

3,500 Two safety chains must be used | 4177-35 |

10mm S WLL 1.0T | 17.2 / 19.7 |

Alternatively, use a shackle that is compatible with the safety chain.

Here are more tips for using a shackle:

- Usually, the diameter of a shackle pin is larger than the shackle body.

- The strength of a shackle varies according to its grade. An 'S' grade shackle is stronger than an 'M' grade shackle of the same size.

- Stainless steel shackles are generally unsuitable for trailers, as they have low resistance to bending stresses.

- A bow shackle provides flexibility for more angular movement than a 'D' shackle.

Vehicle Standards Bulletin VSB1 outlines the minimum requirements for safety chains, shackles and couplings.

Weight distribution hitch

Many towing drivers use a weight distribution hitch, particularly when towing large caravans.

This device transfers some of the load on the tow bar ball to the towing vehicle's front and rear suspension. This maintains the vehicle's ride height and steering control.

You should use heavy duty tow bars and attachments with a weight distribution hitch. Get advice from the tow bar manufacturer or caravan dealer before using this equipment, as it may overload the tow bar and its components.

Caution

Never use a weight distribution hitch to compensate for a badly loaded trailer.

Signage

A combination (tow vehicle and trailer) that’s 7.5m or longer may be fitted with rear marker plates displaying ‘DO NOT OVERTAKE TURNING VEHICLE’. This is mandatory if your vehicle needs to straddle 2 lanes when making sharp turns.

Rear marker plates must comply with the National code of practice for rear marking plates (VSB12).

Examples of rear marking plates

A-frame towing

A motor vehicle can be flat-towed behind another motor vehicle, using a device commonly known as an A-frame. In this case all the wheels of the towed vehicle remain on the road. When towing using an A-frame, the safety requirements stated above continue to apply.

An A-frame consists of a triangle-shaped frame which provides a means of towing a motor vehicle. This towing mechanism is used to tow a vehicle without lifting the towed vehicle clear off the ground. Both the towing and towed vehicles must be registered.

This advice applies to towing vehicles that have a Gross Vehicle Mass (GVM) of 4,500kg or less. For information about towing vehicles with a GVM that exceeds 4,500kg, contact the National Heavy Vehicle Regulator by visiting www.nhvr.gov.au or telephone 13 64 87.

Towed mass ratio

The simplest form of A-frame towing involves towing another vehicle without applying its service brakes. To provide for adequate levels of vehicle stability, handling and braking performance, it is necessary to maintain a towed mass ratio of not less than 3.5:1. This means the mass of the towing vehicle must be at least 3.5 times the mass of an un-braked vehicle being towed (that is, if the mass of the towed vehicle is 1,000kg, the mass of the towing vehicle must be no less than 3,500kg). If the towing vehicle is less than 3.5 times the mass of the towed vehicle, the brakes on the towed vehicle must be used.

Design of A-frame

The A-frame must:

- Be designed and constructed with sufficient strength relevant to the mass of the towed vehicle. Typically, a trailer drawbar (hinged type) strength requirement in ADR 62/... would be relevant to A frame strength.

- Have an ADR 62/... compliant tow coupling of adequate strength at its front end.

- Be secured to a substantial body/frame member of the towed vehicle, such as a sub-frame or chassis member. Connection to the towed vehicle 's bumper, suspension or steering components is not permitted.

- Be marked with the A-frame manufacturer's name or trademark and the maximum mass that is rated to tow.

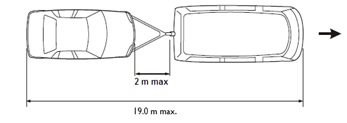

- Maintain a space between the towing and towed vehicles of not more than 2 metres; and

- Not cause the overall length of the vehicle combination to exceed 19 metres.

The A-frame must be equipped with safety chains/cables that meet the same Safety Chain requirements for trailers as described above.

A-Frame towing braking requirements

The requirement for a 3.5:1 towed mass ratio is intended to give the combination adequate braking without the need for the brakes on the towed vehicle to be operated.

The vehicle combination must meet the braking performance specified below:

| Vehicle combination gross mass | Maximum stopping distance when brakes applied at 35km/ | Minimum average deceleration rate from any legal speed | Minimum peak deceleration rate from any legal speed |

|---|---|---|---|

| Under 2.5 tonnes | 12.5m | 3.8 m/s2 | 5.9 m/s2 |

| 2.5 tonnes or over | 16.5m | 2.8 m/s2 | 4.4 m/s2 |

The parking brake of the towing vehicle must be able to hold the combination stationary on a 12 per cent gradient, when the combination is on a dry, smooth road surface, free from loose material.

Lighting requirements for vehicles towed by an A-frame

The following lights must be fitted to the rear of the towed vehicle and must operate in unison with the towing vehicle whilst under tow:

- Two amber turn signals

- Two red stop lamps

- One white reverse lamp

- One registration plate lamp at the rear of the towed vehicle to illuminate the registration plate.

- Two red rear position (tail) lamps.

These lamps may be the towed vehicle's own lights or as an alternative be arranged on a portable light bar providing it is properly secured to the rear of the towed vehicle and comply with the lighting positions shown in Vehicle Standards Bulletin VSB1, Chapter 6.

Steering requirements for vehicles towed by an A-frame

The vehicle combination must be capable of turning within a 25-metre diameter circle, measured at the outer wheel track.

When travelling in a straight line on a level, smooth surface the towed vehicle must track (follow) in the path of the towing vehicle without deviating off-line by more than 100mm.

It is recommended that the tow-ball or hitch position on the towing vehicle is located as close as practicable to the rear axle. This will reduce any adverse effects of the towed vehicle on the handling characteristics of the combination.

Loads in the towed vehicle

Carrying a load in the towed vehicle is permitted. However, it is important to consider the following points:

- The loaded mass of the towed vehicle must not exceed its GVM and the capacity of the mechanical connection, including A-frame, coupling and the towbar.

- If the towed vehicle is unbraked, the laden mass of the towed vehicle must not exceed the limit set by the 3.5:1 towing ratio requirement.

- Any load carried in the towed vehicle should be placed as low as possible and placed toward the rear of the vehicle. Loading toward the rear will reduce the load on the front axle, reducing the tendency of the towed vehicle to worsen the handling characteristics of the combination.

Vehicle under tow sign

It is optional to display a sign indicating a vehicle is under tow.